Condoms need to be reliable. When we use a condom, we are depending on it to do what it was made to do…protect us against sexually transmitted diseases and unwanted pregnancy. The worst thing that can happen is when a condom breaks, slips off, or leaks. For this reason, condoms have to go through a series of quality-control testing that meets regulatory standards. So let’s learn about how condoms are tested.

When we use a condom, we are depending on it to do what it was made to do. If the condom fails, this can have a severe negative impact on our life. Certain sexual transmitted diseases are not curable, such as the HIV, the virus that eventually leads to AIDS. Other sexually transmitted diseases can affect your chances of having children in the future. A product like this has to do what it was designed to do. That is why condom manufacturers go through a system of rigorous testing to ensure that the condoms they produce exceed the highest quality standards. During the manufacturing process, condoms undergo a battery of tests. Although different manufacturers may have some variation as to how they perform their testing, condoms all go through a similar type of quality testing.

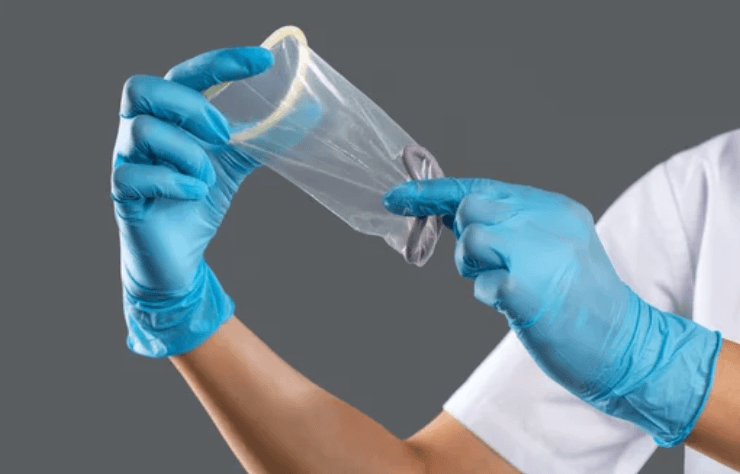

Condom manufacturers tests for leaks or holes in the condoms. Manufacturers such as Lifestyles Brand condoms fill their condoms with 300ml of water to check for pinholes, imperfections, and other defects. Another way condoms are tested for leaks is through a wet and dry test using electricity. In the wet test, condoms are placed over metal rods that are dipped in a conductive solution. When electricity passes through the solution, it passes through any holes or thin areas in the condoms. A computer then measures the current and detects which of the condoms fail the test. In the dry test, higher jolts of electricity are used. This time, a conductive material passed over the condoms that are placed on electrified metal rods. The current passes through any holes or thin areas, which then burn or melt the condom.

Manufacturers also put their condoms through air inflation tests to check for the burst strength and elasticity of the condom. If the inflated condom bursts before it reaches a certain volume, then the sample condom fails and the lots associated with this sample are rejected and destroyed. Condoms are also tested to measure their tensile strength, which tests the condom ability to stretch like a rubber band.

Once the condoms pass all the stages of testing and meet the quality control standards, they are then sent to the distributors and retailers. Even though condoms do go through rigorous testing, it is important for the user to know how to properly use the condom as well. Condoms must be used with each sexual act. Condoms should also be stored in a cool, dry area and be used within the expiration date.